RELAB Laboratory is equipped with two calibrated calorimeters for testing appliances having rated power up to 100 kW and with test benches for testing domestic hot water heat pumps, gas heat pumps and heat recovery devices. In the climatic chambers of the calorimeter up to 100kW, acoustic tests according to the reference standards are carried out.

In detail:

The calorimeter consists of two climatic chambers (indoor chamber and outdoor chamber) which allow reproducing the typical operating conditions (residential, commercial, technical) at which the tested appliances work. These conditions are reproduced in terms of temperature and humidity of the indoor and outdoor environments. In detail: in the indoor chamber, the air temperature (DB) can vary from 0°C to 60°C; while in the outdoor chamber, from -30°C to 60°C. Hydronic circuits positioned inside each chamber allow instead to reproduce flow rates from 0.1 m3/h to 5m3/h.

The calorimeter consists of two climatic chambers (chamber 1and chamber 2) each one able to test appliances having rated power up to 50 kW. By removing the separating wall between the two chamber, it’s possible to obtain a unique chamber able to test monoblock appliances having rated power up to 100kW. Both chambers are able to reproduce the operating conditions in terms of temperature (from -30°C to 60°C) and humidity prescribed by the reference standards. Hydronic circuits inside each chamber allow reproducing flow rates up to 25m3/h..

Features and Operating range of the two calorimeters (up to 25kW and up to100kW)

| QUANTITY | OPERATING RANGES |

| Air Temperature – Indoor Chamber | 5°C ÷ +60°C |

| Air Temperature – Outdoor Chamber | -30°C ÷ +60°C |

| Relative Humidity | 20% ÷ 95% |

| Heat transfer medium (water/brine) temperature | -20°C ÷ +95°C |

| Heat transfer medium (water/brine) flow rate. Calorimeter up to 25kW | Low= Q<1 m3/h ; High= 1<Q<5 m3/h |

| Heat transfer medium (water/brine) flow rate. Calorimeter up to 100kW | Low=Q<1 m3/h – Medium=1<Q<5 m3/h – High 5<Q<25 m3/h |

| Voltage | 0V to 460V |

| Current | up to 100A |

| Frequency | 50Hz (predisp. per 60Hz) (predisp. per 60 Hz) |

| Frequency band (for acoustic tests) | 100Hz÷10kHz |

The chambers of the two calorimeters can be used both separately, for testing monoblock appliances, and simultaneously for testing split (with external and internal units) and ducted appliances.

Besides the air conditions, the calorimeters allow controlling temperatures and flow rates of the heat transfer medium (water and brine) into the appliances.

The instrumentation employed in the laboratory allows the assessment of performances (COP, SCOP, EER and SEER) and thermal outputs of the tested appliances as required by technical regulations. It allows also to monitor the main quantities of interest, i.e.: electrical quantities (power, current, voltage, electric phase shift etc.), flow rates, temperatures, pressure losses on the hydronic circuits, RPM, air speed of all test units. Then pressure and/or static pressure difference of ducted units; gas consumption and gas pressure of gas heat pumps.

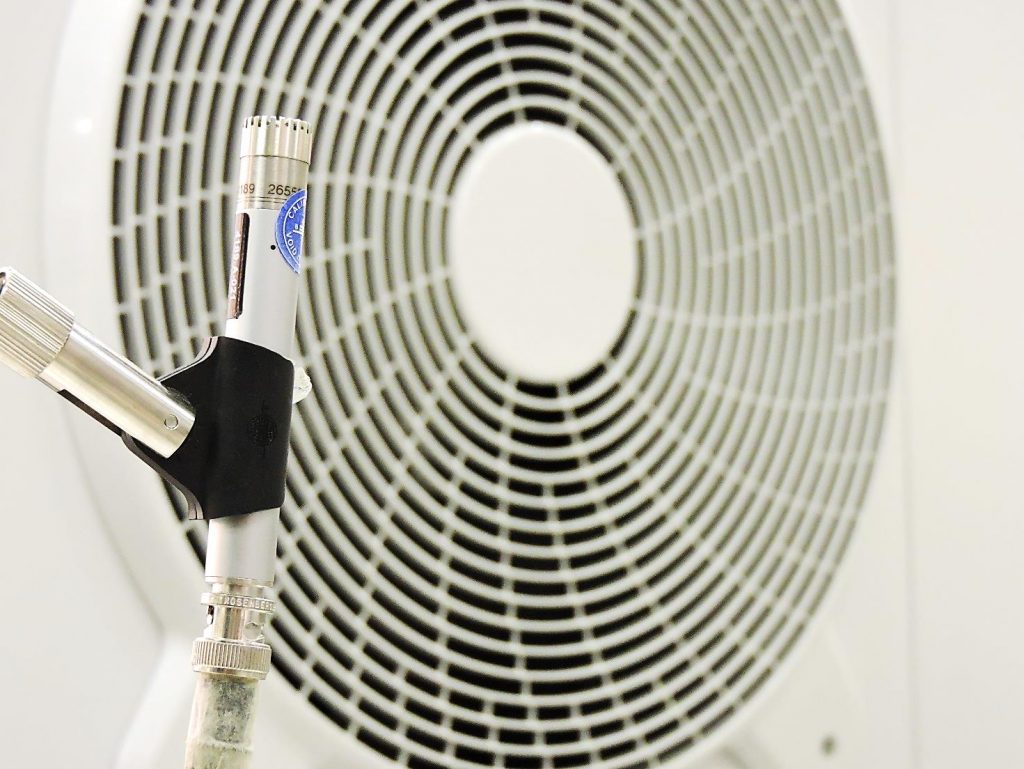

In particular, the sound power level of the source under test (e.g. heat pump, fan coil, ..) is determined through the disposition, within the chambers and around it, of microphones connected to a multi-channel analyzer. Furthermore, through special set-up inside the chambers, it is also possible to carry out intensity tests and, by disposing microphone arrays, also to map the directivity and sound power of the source under test.

The laboratory provides high-level measuring instruments, calibrated at accredited laboratories and constantly checked and maintained. Each measurement is duplicated in order to verify continuously the measurement process and to allow a more in-depth analysis of the monitored data.

| QUANTITY | TYPE OF INSTRUMENTATION | ACCURACY |

| Water/brine flow rate | Mass Flow Meter | Class 0,1% |

| Water/brine flow rate | Electromagnetic Flow Meter | Class 0,2% |

| (Methane) Gas flow rate | Tumble Flow Meter | Class 0,2% |

| Temperature | Platinum Thermal Resistance – PT100 | Class 1/10 DIN |

| Temperature | Reference standard Thermometer for PT100 sensor | System Accuracy 0.04°C |

| Pressure | Differential Pressure Transmitter | Class ±0.075%: |

| Pressure | Pressure Transmitter | Class ±0.4%: |

| Dew Point | Chilled Mirror | ±0.2°C Dew Point – 0,1°C Tdb |

| Electricity | Wattmetro – Analyzer | Class ±0.2% |

| Sound Pressure | Multichannel Analyzer + microphones | Class 1 |

| Sound Intensity | Phonometer + intensity probe | Class 1 |

| Sound pressure, Intensity, Power | microphone arrays | (Class 1 microphones) |

Both the 25kW calorimeter and the 100kW calorimeter are equipped with a test bench for testing heat pumps for domestic hot water (DHW) production. In both facilities, hydronic circuits and instrumentation are designed for carrying out tests in accordance with EN16147 requirements.

The test benches are completely automated. They are able to: test domestic hot water production systems with integrated or separated storage; to perform standardized or ad-hoc (based on manufacture’s request) draw-off profiles; to monitor all quantities of interest such as: domestic hot water flow rate, inlet/outlet domestic hot water temperature; tank temperature; water pressure; pressure and thermal losses; electric quantities and consumptions.

In the chambers of both calorimeters, test benches for testing gas fired appliances such as sorption heat pumps, hybrid heat pumps, boilers and endothermic heat pumps are positioned.

The chambers were these test benches are in, are equipped with all safety equipment and instrumentation to perform tests in accordance with the reference standards (i.e. EN 12309 and VDI 4650 Part 2). Furthermore there’s a main switch that allow swap from grid gas to certified gas in bottles and vice versa in case of accredited tests or research and development of new products which use different gases.

The test benches are then managed by a dedicated tool able to monitor and to record all relevant quantities such as: air temperature and humidity; water/brine flow rate; gas flow rate and gas pressure; water/brine and gas inlet/outlet temperature; pressure losses on hydronic side and electric quantities.

The Laboratory is equipped with phonometers, microphones, intensity probes, acoustic calibrators, reference sound sources, a multichannel analyzer which allows different types of measurements and a multichannel system with microphones array for sound mapping via beamforming and acoustic holography.

This instrumentation allows to carry out: